That is, the engineering side of getting a vessel’s propulsion and steering systems ready for sea. How things change.

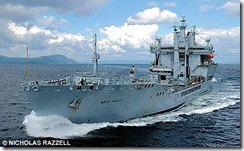

Lets take the case of an improved RFA Fort class vessel of about twenty years of age, and a Wave class of approximately five years of age.

The Fort class vessel.

Ensure that there is enough spinning reserve being generated from the diesel generators. (Although the vessel allegedly had a power management system I prefer to call it a mismanagement system).

Head three levels down to the bottom of the engine room.

Turn both engines on turning gear for two complete revolutions each.

Disengage turning gear.

Kick over engines on air without fuel.

Close all 32 indicator cocks.

Put safety caps on cocks.

Turn on fuel and run both engines ahead and astern on fuel from local position next to the engines.

Test local telegraphs with the bridge Officer.

Test clutches and shaft brakes locally.

Remember to switch control of engines to remote.

Go to control room. (Out of breath)

Test telegraphs with Bridge.

Go round the back of the manoeuvring console and reset electric governors. (Don’t leave this step out, Things could get frightening otherwise).

Test clutches and brakes in manual MCR control.

Test engines ahead and astern in manual control.

Test engines , clutches and brakes in MCR auto control.

Test Engines, clutches, and brakes, in Bridge control.

Head off down to the steering flat.

Test all 4 humungous electro-hydraulic steering motors in local manual control.

Test all four steering motors in push button local control.

Pass control to the bridge and have it all tested from there..

Go back to the MCR and wipe sweat from your brow. Approximate time for this as a lone engineer evolution. (If done properly) 1 1/2 hours at least..

The Wave class vessel.

Put kettle on.

From the MCR, test telegraphs with the bridge.

Contact the systems engineer in the sychroconverter room and tell him to do likewise.

Make tea.

Place cursor over one of the harmonic filters and “click*

Start main motors with a judicious “click” on the right place on the screen.

Use tiny little lever to test the propeller rotates ahead and astern.

Contact systems engineer and tell him to do the same.

Swig tea.

On completion pass control to the bridge and get the officer of the day to do the same.

Swig more tea.

“Click” on bow thruster and stern thruster start, and test from MCR and bridge.

Tea’s still hot.

Nip down to the steering flat and test the two motors in the same way as the Fort class.

Go back to the MCR. Time taken. About the time it takes for the tea to go from piping hot, to warm.

This post is just to show that technology is changing the way we do things in the field of marine engineering. The order of testing I’ve written maybe slightly wrong but the time taken is the thrust of this post. (we all get old).

ED’s Note:

The first vessel had a twin engine, twin screw, direct drive setup operating through gearboxes and clutches.

The second vessel was a diesel electric, single screw system. The primary source of power was a power management system powering two DC motors attached to a single shaft.

Footnote: Sadly the RFA Fort George has now been scrapped and cut up for razor blades.

PS. Another Filthy Engineer. Give me a clue to your identity if you’re reading this. Just give me the first letter of your surname. You can contact me anyway at Niklowe@gmail.com.

Is a diesel electric drive more efficient in energy terms than a direct drive diesel transmission?

ReplyDeleteIt depends what the role of the ship is. If you're just going from A to B at a set speed, then a long stroke diesel engine makes sense. However if your ship is a jack of all trades and has to sail at low and high speeds then diesel electric makes sense.

ReplyDelete